To lubricate an extension ladder, apply a silicone lubricant along the ladder’s moving parts and joints. This helps reduce friction and ensures smooth operation.

Proper lubrication is essential to maintain the ladder’s functionality and prevent accidents. An extension ladder is a valuable tool for various tasks, such as reaching high places or working on roofs. However, over time, the ladder’s moving parts may become stiff and difficult to extend or retract.

Fortunately, lubricating the ladder can address this issue. By applying silicone lubricant to the ladder’s moving parts and joints, you can reduce friction and ensure smooth operation.

This simple maintenance step helps prolong the ladder’s lifespan and ensures safe and efficient use. I will discuss the steps involved in lubricating an extension ladder to keep it in top condition.

Why Lubricating Your Extension Ladder Is Important

Regular maintenance is essential for keeping your extension ladder operating smoothly and ensuring its longevity. One crucial aspect of ladder maintenance is proper lubrication. Lubricating your ladder not only reduces friction and wear but also improves its overall performance and safety.

In this section, I will explore the importance of regular maintenance, the benefits of lubrication, and how proper lubrication enhances ladder performance.

Importance Of Regular Maintenance For Extension Ladders

Performing regular maintenance on your extension ladder is the key to avoiding accidents and prolonging its lifespan. By implementing routine inspections and lubrication, you can identify and address any potential issues before they escalate into major problems.

Regular maintenance allows you to:

- Ensure that all ladder components are in good working condition.

- Identify and rectify any loose or damaged parts.

- Prevent rust and corrosion from compromising the ladder’s structural integrity.

- Address any lubrication needs to maintain optimal performance.

Benefits Of Lubricating An Extension Ladder

Lubricating your extension ladder offers a range of benefits that contribute to its smooth operation and longevity. Here are some advantages of regular lubrication:

- Prolonged lifespan by reducing friction and minimizing wear on moving parts.

- Enhanced durability by preventing rust and corrosion.

- Improved ease of extension and retraction, reducing strain on your body.

- Minimized risk of accidents, as lubrication reduces the likelihood of sudden jerks or failures.

- Preserved functionality, ensuring that the ladder operates as intended.

How Proper Lubrication Improves Ladder Performance

Proper lubrication plays a crucial role in enhancing the overall performance of your extension ladder. When you lubricate your ladder correctly:

- You reduce friction between the ladder’s moving parts, allowing smoother extension and retraction.

- The lubricant acts as a protective barrier against moisture, preventing rust and corrosion.

- The ladder’s joints and hinges remain supple and responsive, minimizing the risk of sudden collapses or accidents.

- The lubricant helps to keep the ladder clean by repelling dirt and debris.

By implementing regular lubrication as part of your ladder maintenance routine, you not only ensure its optimal performance but also increase its lifespan, safety, and reliability.

Safety Precautions For Lubricating An Extension Ladder

Lubricating an extension ladder is essential to ensure smooth and safe operation. However, it is crucial to take proper safety precautions when performing this task to minimize the risk of accidents and injuries.

In this section, I will discuss the importance of following safety guidelines when working with extension ladders and provide tips on how to handle the ladder safely during the lubrication process. I will also recommend personal protective equipment (PPE) to ensure your safety.

Importance Of Following Safety Guidelines When Working With Extension Ladders

When it comes to working with extension ladders, safety should always be your top priority. Extension ladders can pose various risks if not handled properly during lubrication. By following safety guidelines, you can mitigate these risks and prevent accidents from occurring.

Ensure the ladder is in good condition before starting the lubrication process. Inspect for any damages, cracks, or missing parts that could compromise its stability.

Choose a stable and level ground for placing your ladder. Make sure the surface is free from any debris, slippery substances, or uneven terrain that may cause the ladder to wobble or shift.

Position the ladder at the correct angle. The ratio for extension ladders is known as the “4-to-1 rule.” For every four feet of ladder height, the base should be one foot away from the supporting wall or vertical surface.

Secure the ladder by locking the rung locks or engaging any other safety mechanisms provided. This will prevent the ladder from collapsing or accidentally retracting while you work.

Avoid overreaching or leaning too far to either side when lubricating the ladder. Always maintain your balance, and if you need to reach a different area, reposition the ladder instead of stretching beyond your reach.

Tips For Safely Handling A Ladder During Lubrication

Proper ladder handling techniques are crucial for your safety and the stability of the ladder during the lubrication process. Keep these tips in mind to ensure safe ladder usage:

- Always maintain three points of contact with the ladder, such as two hands and one foot, or two feet and one hand. This will help you stay balanced and prevent falls.

- Avoid sudden movements or jerking actions when on the ladder, as this can destabilize it. Move slowly and deliberately.

- If possible, use a ladder stabilizer or stand-off device to provide additional support and prevent the ladder from damaging the surface it rests against.

- Consider enlisting the help of a second person to hold the ladder steady while you lubricate it. This extra pair of hands can make the process safer and more efficient.

Recommendations For Personal Protective Equipment (PPE)

Protecting yourself with the right personal protective equipment (PPE) is vital whenever you are working with extension ladders. The following are some key recommendations:

| PPE | Description |

|---|---|

| Safety glasses/goggles | Protects your eyes from any debris or splashes that may occur during lubrication. |

| Gloves | Provides a better grip on the ladder and safeguards your hands from any sharp edges. |

| Non-slip shoes | Ensures stability and prevents accidental slips on the ladder or surrounding area. |

| Protective clothing | Wear long sleeves and pants to shield your skin from potential scratches or cuts when handling the ladder. |

By adhering to these safety precautions and utilizing appropriate personal protective equipment, you can lubricate your extension ladder with confidence and minimize the risk of accidents. Remember, safety should always come first in any maintenance task involving ladders.

Steps To Lubricate An Extension Ladder

Proper maintenance is essential to keep your extension ladder in top shape for safe and efficient use. One crucial aspect of maintenance is regular lubrication, which helps prevent rust, corrosion, and sticking parts. In this section, I will guide you through the necessary steps to lubricate your extension ladder effectively.

Gathering The Necessary Tools And Materials

Before you begin, it’s essential to gather all the tools and materials you’ll need for the lubrication process. Having everything ready ensures a smooth and uninterrupted workflow. Here are the items you’ll need:

- Extension ladder lubricant (such as graphite powder or silicone spray)

- Clean cloth or rag

- Brush or small scrubbing tool

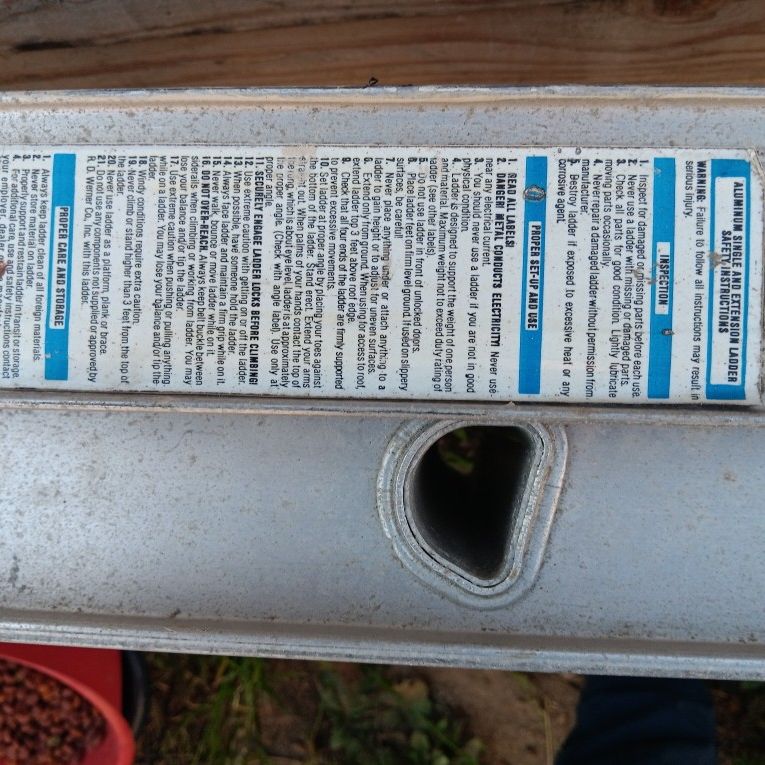

Inspecting The Ladder For Any Damage Or Defects

Prior to lubrication, it’s crucial to inspect your extension ladder thoroughly for any signs of damage or defects. Identifying and addressing these issues before applying lubricant can help avoid safety hazards or further damage. Here’s what you should look for:

- Cracks or breaks in ladder components

- Loose or missing screws, bolts, or rivets

- Worn or damaged rungs

- Any signs of excessive rust or corrosion

Cleaning The Ladder Before Applying Lubricant

For the lubricant to work effectively, the ladder’s surfaces need to be clean and free from dirt, debris, or old lubricant residue. Follow these steps to clean your extension ladder:

- Use a brush or small scrubbing tool to remove any loose dirt, dust, or debris from the ladder’s rungs and other components.

- Wipe the ladder down with a clean cloth or rag to remove any remaining particles.

- Inspect and clean hard-to-reach areas, such as hinges or sliding mechanisms, using a small brush or toothbrush if necessary.

Applying Lubricant To The Necessary Parts Of The Ladder

Once your ladder is clean and dry, it’s time to apply the lubricant to the required parts. The specific areas that need lubrication may vary depending on the ladder type and model, but here are the most common ones:

| Parts to Lubricate | Recommended Lubricant |

|---|---|

| Hinges and pivot points | Graphite powder or silicone spray |

| Sliding mechanisms | Graphite powder or dry lubricant spray |

| Locking mechanisms | Graphite powder or silicone spray |

Distributing And Spreading The Lubricant Evenly

After applying the lubricant to the necessary parts, it’s essential to ensure even distribution for optimal performance. Here’s how to do it:

- Operate the ladder a few times to allow the lubricant to spread and penetrate the moving parts.

- If required, add more lubricant to areas that seem dry or sticky.

Wiping Off Excess Lubricant

Finally, it’s crucial to wipe off any excess lubricant to prevent it from attracting dirt or becoming a potential slipping hazard. Use a clean cloth or rag to gently remove the excess lubricant from the ladder’s surfaces. Pay close attention to any crevices, corners, or small moving parts.

Credit: offerup.com

Types Of Lubricants for Extension Ladders

Types of lubricants for extension ladders include silicone-based sprays, graphite powders, and dry lubricants. Proper lubrication is essential to keep the ladder working smoothly, prevent rust and corrosion, and ensure safe usage.

Your extension ladder is a valuable tool that helps you reach new heights of productivity. To ensure its smooth operation and longevity, proper lubrication is essential. However, choosing the right lubricant can sometimes be a daunting task.

In this section, I will explore the various types of lubricants available for extension ladders, their advantages, and disadvantages, and provide you with the necessary knowledge to make an informed decision for your ladder’s maintenance.

Overview Of Different Types Of Lubricants Available

When it comes to lubricating your extension ladder, several types of lubricants can get the job done. Here are the most common ones:

| Lubricant Type | Description |

|---|---|

| Penetrating lubricants (e.g., WD-40) | These lubricants are specially formulated to seep into tight spaces and displace moisture, making them an excellent choice for removing rust, dirt, and grime. They often come in aerosol cans, allowing for easy application. |

| Grease | Grease lubricants, characterized by their thick and sticky consistency, provide long-lasting lubrication and protection against corrosion. They are suitable for heavy-duty applications and can withstand high temperatures. |

| Dry lubricants (e.g., graphite powder) | Dry lubricants are ideal for situations where traditional liquid lubricants may attract dust or dirt. They create a thin, friction-reducing layer between surfaces without leaving any residue. |

Advantages And Disadvantages Of Each Type Of Lubricant

Each type of lubricant has its own set of advantages and disadvantages, which should be considered when selecting the right one for your extension ladder:

Penetrating lubricants (e.g., WD-40)

Advantages include their ability to remove rust and dirt, as well as their versatility for multiple applications. However, they may not provide long-lasting lubrication and may require more frequent reapplication compared to other types.

Grease

The main advantage of grease lubricants is their durability and ability to withstand heavy loads and high temperatures. However, their sticky nature may attract dust and dirt over time.

Dry lubricants (e.g., graphite powder)

Dry lubricants excel at reducing friction without leaving residue, making them ideal for applications where cleanliness is crucial. However, they may not provide as long-lasting lubrication as other types and may require more frequent reapplication.

Choosing The Right Lubricant For Your Extension Ladder

Choosing the right lubricant for your extension ladder depends on various factors, including the ladder’s materials, usage conditions, and your specific requirements.

Consider the following guidelines:

Material compatibility: Ensure that the lubricant you choose is safe for use on the materials of your extension ladder, such as aluminum or fiberglass.

Usage conditions: Consider the environment in which your ladder operates. If you frequently work in dusty or dirty areas, a dry lubricant might be more suitable to avoid attracting debris.

Longevity: Assess how long-lasting the lubricant needs to be for your ladder’s specific usage. If you use your ladder intensively or in demanding conditions, a grease lubricant might provide better long-term protection.

By considering these factors and understanding the advantages and disadvantages of each lubricant type, you can make an informed decision and ensure that your extension ladder operates smoothly and reliably for years to come.

Maintenance Tips To Extend The Lifespan Of Your Extension Ladder

Extend the lifespan of your extension ladder with these maintenance tips. Learn how to lubricate your ladder properly to ensure smooth and safe operation, enhancing its durability over time.

Importance Of Regular Maintenance For Ladder Longevity

Regular maintenance is vital to ensure the long-lasting performance and safety of your extension ladder. By taking proactive measures to care for your ladder, you can prevent potential accidents and extend its lifespan. Neglecting maintenance can lead to rust, corrosion, and other issues that compromise the ladder’s structural integrity.

Keep in mind that safety should always be a top priority when using a ladder, and regular maintenance plays a crucial role in ensuring its stability. Let’s take a closer look at some key maintenance tips to help you get started.

Inspecting And Cleaning The Ladder After Each Use

Inspecting and cleaning your extension ladder after every use is a simple yet effective way to detect any damage or wear and tear. Start by visually examining the ladder for any signs of rust, chipped paint, or loose connections.

Ensure that all rungs and locks are securely in place. Pay close attention to the ladder feet and ensure they are free from dirt and debris, as this can affect stability.

Using a damp cloth or sponge with a mild detergent, thoroughly clean the ladder to remove any dust, grime, or grease that may have accumulated during use. Once cleaned, allow the ladder to air-dry before storage.

Storing The Ladder In A Suitable Environment

Proper storage is essential to protect your extension ladder and maintain its condition. When not in use, store the ladder in a dry and sheltered location, away from direct sunlight, extreme temperatures, and moisture.

Exposure to harsh weather conditions can accelerate deterioration and weaken the ladder’s components. Consider utilizing a ladder storage rack or hooks to keep it off the ground and prevent bending or warping. Remember, storing your ladder in a suitable environment helps prolong its lifespan and ensures it’s ready for safe use when needed.

Proper Handling And Transport Of The Ladder

To prevent unnecessary strain or damage, it’s crucial to handle and transport your extension ladder correctly. When moving the ladder, always carry it in an upright position, gripping the rungs with both hands. Avoid resting the ladder against sharp or abrasive surfaces that can cause scratches or dents.

If you need to transport the ladder on a vehicle, secure it using sturdy straps and ensure it remains stable during transit. By following proper handling and transportation practices, you can minimize the risk of accidents and maintain the ladder’s structural integrity.

Scheduling Routine Maintenance And Inspection

Consistent maintenance and inspection should be a part of your ladder maintenance routine. Set a schedule to regularly check your extension ladder for any signs of damage or wear. This includes inspecting the steps, locks, and overall stability of the ladder. Additionally, ensure that any lubricated parts, such as hinges, are properly maintained to prevent rust and friction.

Taking the time to carry out routine maintenance and inspection allows you to catch and address any potential issues early on, ensuring the continued safety and longevity of your extension ladder.

Remember, by following these maintenance tips, you can enhance the lifespan and reliability of your extension ladder.

Regularly inspecting, cleaning, storing, handling, and conducting routine maintenance and inspection not only keeps your ladder in optimal condition but also provides peace of mind during every use. So, take the necessary steps to care for your ladder and ensure its longevity.

Frequently Asked Questions For How To Lubricate An Extension Ladder

What Is The Best Lubricant For An Extension Ladder?

The best lubricant for an extension ladder is a silicone-based spray or lubricating oil. It helps reduce friction and allows smooth extension and retraction of the ladder. Regular application keeps the ladder in good condition and ensures safe and efficient use.

How Do You Lubricate A Telescoping Ladder?

To lubricate a telescoping ladder, follow these steps:

- 1. Clean the ladder thoroughly, removing any dirt and debris.

- 2. Apply a silicone-based lubricant to the moving parts of the ladder.

- 3. Extend and retract the ladder several times to ensure smooth operation.

- 4. Wipe off any excess lubricant.

- 5. Store the ladder in a dry place to prevent rust and corrosion.

What Is The Maintenance of an Extension Ladder?

To maintain an extension ladder, regularly check for loose or damaged parts, clean it after each use, store it properly in a dry area away from sunlight, and avoid overloading or misusing it. Also, inspect the ladder before each use to ensure it’s safe and secure.

How Do You Maintain An Aluminum Ladder?

To maintain an aluminum ladder, follow these guidelines: 1. Inspect for any damage regularly. 2. Clean with a mild detergent and water. 3. Avoid using harsh chemicals or abrasive materials. 4. Dry thoroughly after cleaning to prevent rust. 5. Store in a dry and secure location to prevent any potential damage.

How Often Do Extension Ladders Need To Be Lubricated?

Extension ladders should be lubricated at least once a year to ensure smooth and safe operation.

What Type Of Lubricant Should I Use On My Extension Ladder?

It is recommended to use a silicone spray lubricant specifically designed for metal surfaces to lubricate your extension ladder.

How Do I Apply Lubricant To My Extension Ladder?

To apply lubricant, simply spray it evenly along the moving parts of the ladder, such as the rungs, hinges, and locking mechanisms.

Final Words

Lubricating an extension ladder is essential for its smooth and safe functioning. Regular maintenance and proper lubrication increase the longevity of the ladder, allowing you to work with confidence.

By following the step-by-step guide provided in this blog post, you can ensure that your extension ladder remains free from rust, operates smoothly, and minimizes the risks of accidents.

Stay proactive in maintaining your ladder, and it will serve you well for years to come.